(remove this paragraph once the translation is finished)

Variant "Write" b) PLC generates product code independently

| Variable | Data type | Description | Direction | |

|---|---|---|---|---|

| Written* | BOOL | This variable sets PLC when new data is available and PLC sets it back to FALSE | From PLC to MES | |

| Written* | BOOL | This variable writes TRUE to MES when the data has been stored in the database. MES resets it to FALSE | From MES to PLC | |

| Product code* | STRING | This variable allows the PLC to specify the unique embossing text to which the data refers | From PLC to MES | |

| Product* | STRING | This variable allows the PLC to specify a product; e.g. the recipe name (can be static) | From PLC to MES | |

| Product ID* | STRING | The generated database GUID is provided by MES to the PLC, so that further measured values can be assigned faster | From MES to PLC | |

| Measured value 1..N* | miscellaneous | The measured values or states of the produced part can be specified here in various data formats | From PLC to MES |

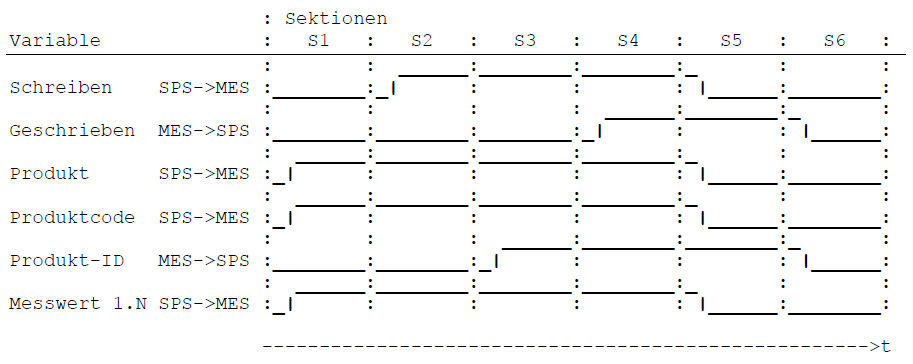

- Section 1:

- {Product} is set by PLC at least 300ms before {Write}.

- {product code} is set by PLC at least 300ms before {write}

- {Measured values 1..N} is set by PLC at least 300ms before {write}

- Section 2:

- {Write} is set by PLC.

- Section 3:

- {Product ID} is set by MES.

- Section 4:

- {Written} is set by MES

- Section 5:

- {Write} is reset by PLC (Reason: rising edge {Write}).

- {Product} is reset by PLC (Reason: rising edge {Written})

- {Product code} is reset by PLC (Reason: rising edge {Written})

- {Measured values 1..N} is reset by the PLC (Reason: rising edge {Written})

- Section 6:

- {Written} is reset by MES (Reason: falling edge of {Written}).

- {Product ID} is reset by MES (Reason: falling edge of {Write})